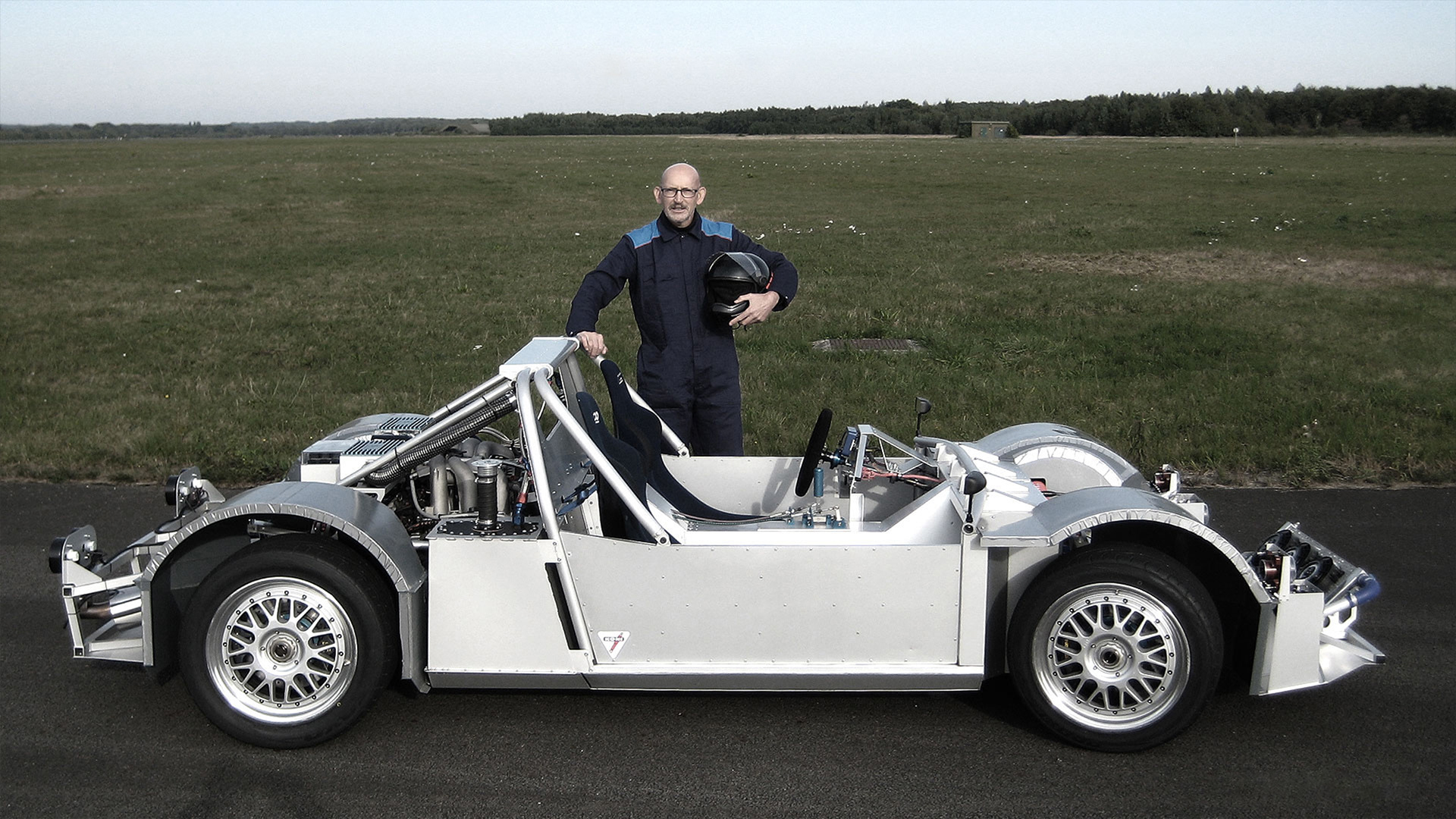

(above) Testing at race track Meppen (Germany). Photo by Marco van Overbeeke

ThE Exterior design OF THE SILVERMINE 11SR track racer - A special collaboration

A couple of years ago I stumbled upon the intriguing story of a company somewhere in The Netherlands that was building a very special race car: Silvermine. Its beautiful race chassis was designed and built by a single man, Frank van Rouendal. The developments and building progress could be followed online and at a certain point the Silvermine 11P prototype chassis was being tested at high speeds on a closed-off airfield. But the car was still missing actual bodywork. So I decided to contact Silvermine and meet the man behind this project. That's how my brother Andries and I met Frank.

'Imagine being a kid and wanting to be a racing driver. Imagine years later seeing yourself become an engineer and dreaming about building your own racing car. Now imagine you take that first step to realize your dream and start designing and fabricating components and slowly putting them together, taking years of perseverance and blood, sweat and tears. Imagine the patience and dedication. And now imagine putting all those things together and seeing come to life. And then finally being able to step into your creation. On track. Accelerating. Full throttle!'

This is exactly what Frank did. His skills as a marine engineer and machine constructor led to a beautiful uncommon piece of engineering, a unique chassis designed and built in his own garage over the course of 10+ years. We had the honour to create the bodywork design for the Silvermine 11SR track racer. Below you can read more about the design process and the engineering details.

3D model and renderings: Andries van Overbeeke, www.andriesvanoverbeeke.com, behance.net/andriesvanoverbeeke

2D sketches: Marco van Overbeeke, www.marcovanoverbeeke.com

More info about Silvermine: www.silvermine.nl

Unless stated otherwise, photography and video by Tjeerd Weerensteijn

(above) The man and his creation. Photos: Marco van Overbeeke

(below) The first time we met Frank the chassis was bare naked. Years later she finally has a body.

(below) Incredible to see the final 3D model (modelling and renderings by Andries van Overbeeke) versus the real thing years later!

The level of detail for a first prototype is impressive.

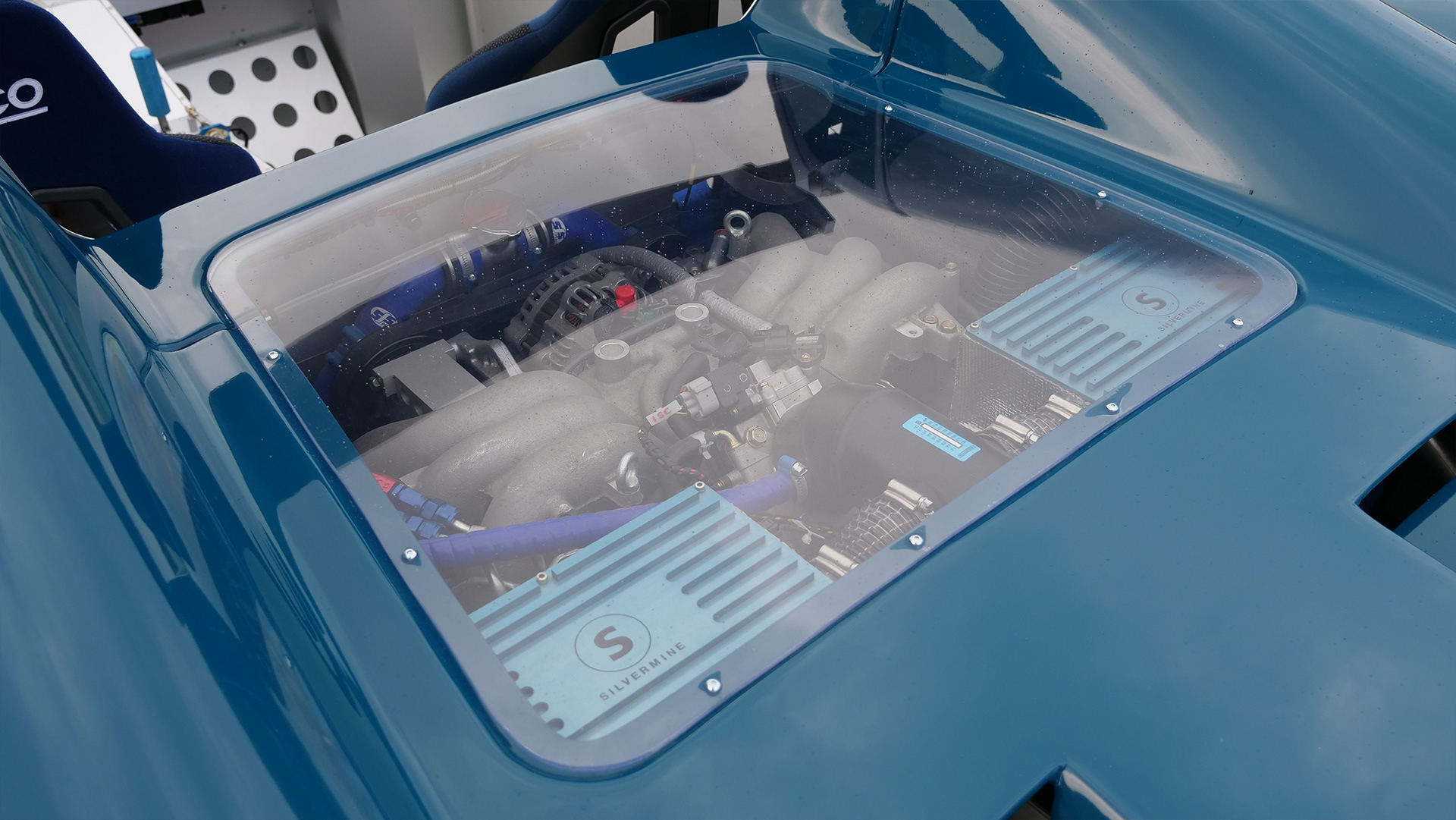

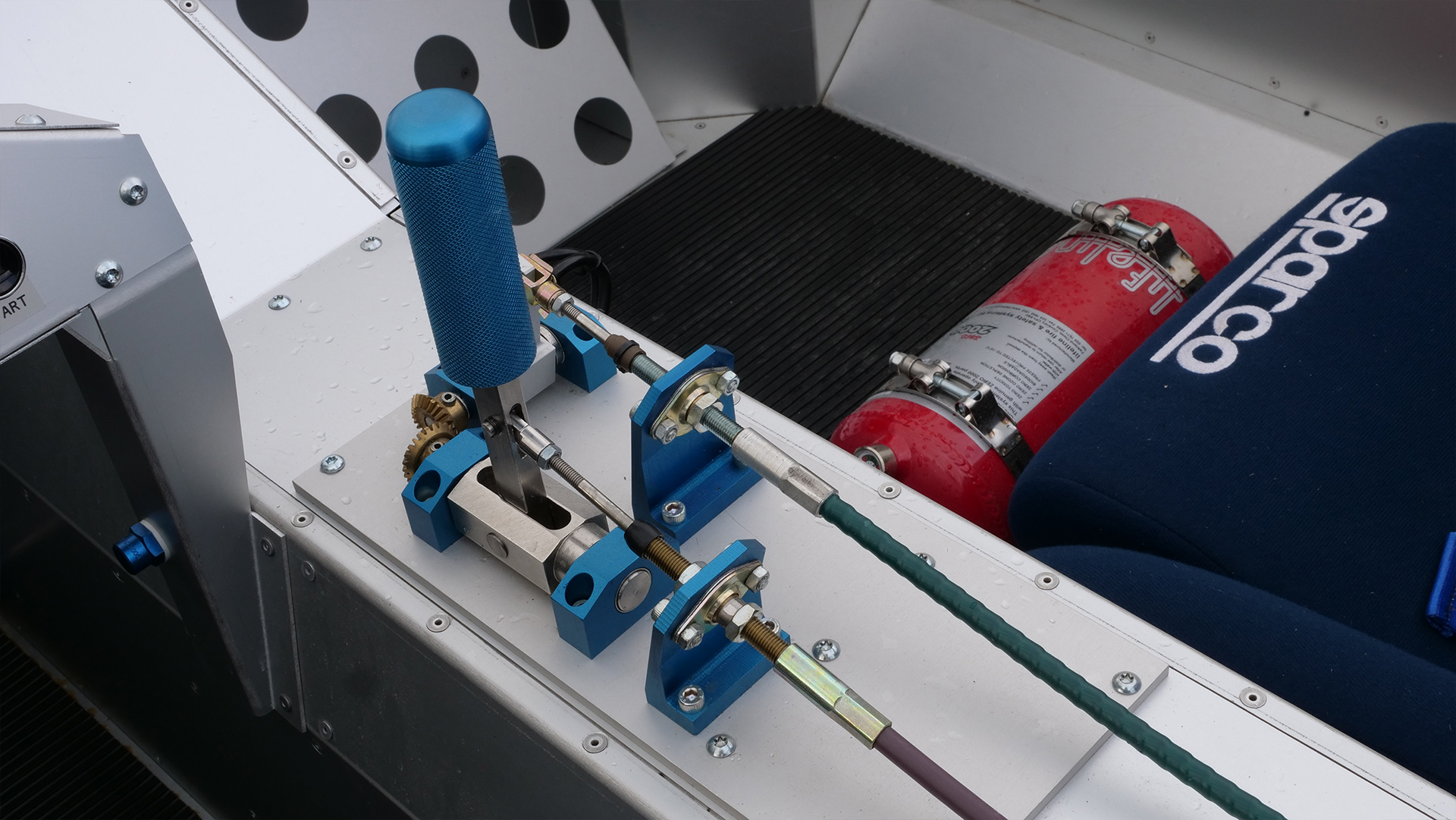

This extremely lightweight racer features a remarkable high quality first prototype body, including fully opening front and rear one piece body shells. The bodywork partly exposes the fully handmade aluminium chassis and roll cage, displaying the car's internal components visible through the headlamp covers, windscreen, open tailgate and engine bay with exposed gearbox and fully adjustable suspension, and a transparent engine cover displaying that raw flat-six power. One-off custom spec BBS wheel design, an all aluminium spartan race interior including fire extinguisher system. Extremely special are the in-house designed and custom fabricated gear lever system, chassis tub and sub frames, roll cage, windshield, suspension and steering system, wheel upright + hub + center lock nut system, hand brake, bespoke springs, tailor made exhaust system, air intakes and filter box system, custom radiator and the list goes on.

Chassis: engineering and suppliers

The unique chassis has been developed from the ground up and completely designed in CAD. Van Rouendal constructed, designed and built the complete prototype chassis in his own garage.

A car like this cannot be developed without the necessary suppliers. Although it is the brainchild of Van Rouendal, he has

cooperated with a number of high quality suppliers and product developers, and each of them has used his

expertise to supply bespoke components for the 11SR. Without the involvement of highly competent suppliers

a project like this could never succeed. Although all parts of the car have been designed and calculated inhouse, a proper technical dialogue with suppliers is essential. In this way the perfect recipe for each specific

component can be attained. The proper alloy, the optimum damper curve, the best suited transmission ratio,

on each front the interaction between designer and supplier results in another piece of this unique product.

cooperated with a number of high quality suppliers and product developers, and each of them has used his

expertise to supply bespoke components for the 11SR. Without the involvement of highly competent suppliers

a project like this could never succeed. Although all parts of the car have been designed and calculated inhouse, a proper technical dialogue with suppliers is essential. In this way the perfect recipe for each specific

component can be attained. The proper alloy, the optimum damper curve, the best suited transmission ratio,

on each front the interaction between designer and supplier results in another piece of this unique product.

In the 11SR it is not difficult to find good examples of this cooperation. Many bespoke components of the car

are based on a supplier’s existing product, adapted to comply with the special requirements that resulted from

the design. This is certainly the case for the gearbox, wheels, brake discs, exhaust system, fuel safety cells, etc.

are based on a supplier’s existing product, adapted to comply with the special requirements that resulted from

the design. This is certainly the case for the gearbox, wheels, brake discs, exhaust system, fuel safety cells, etc.

Exterior design

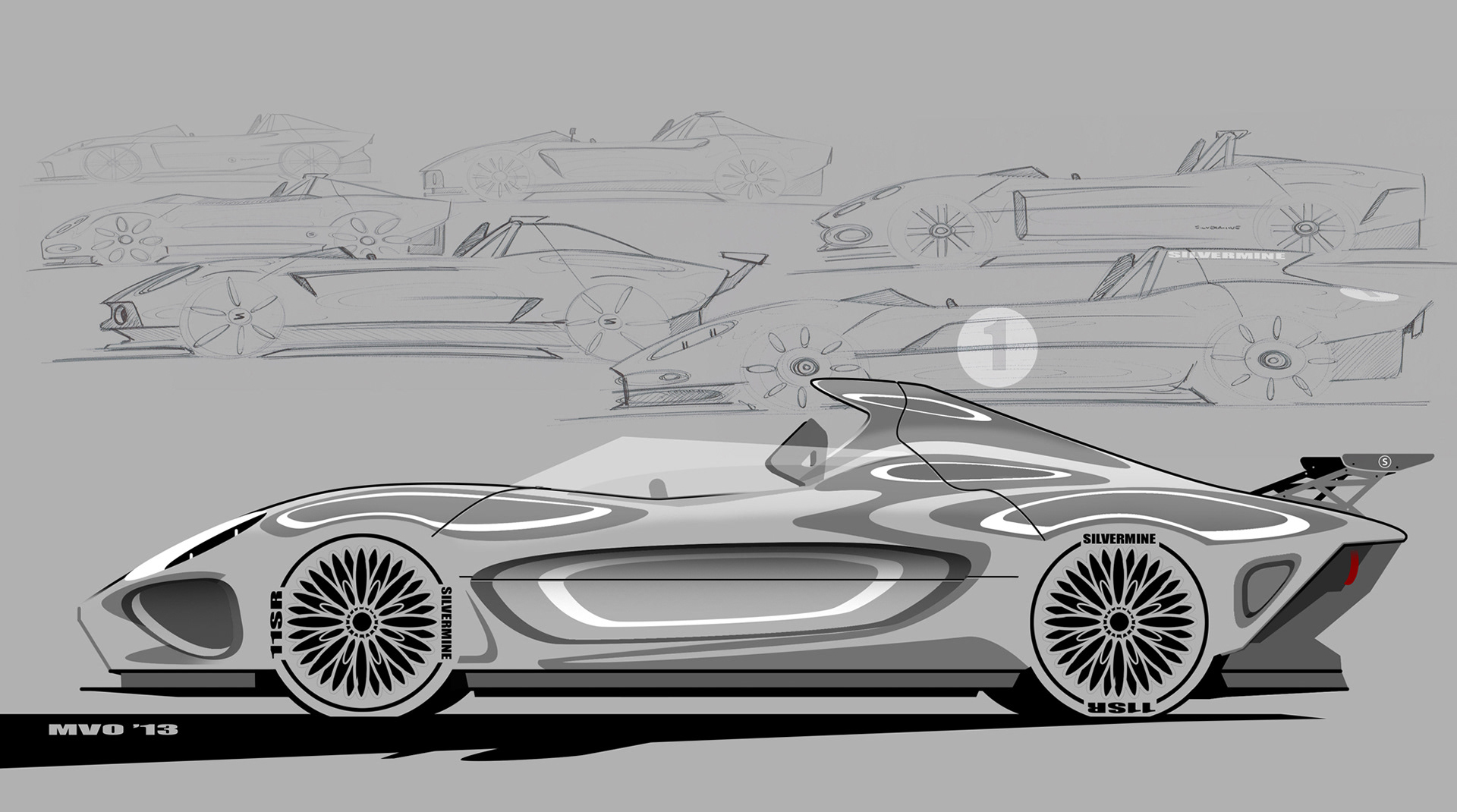

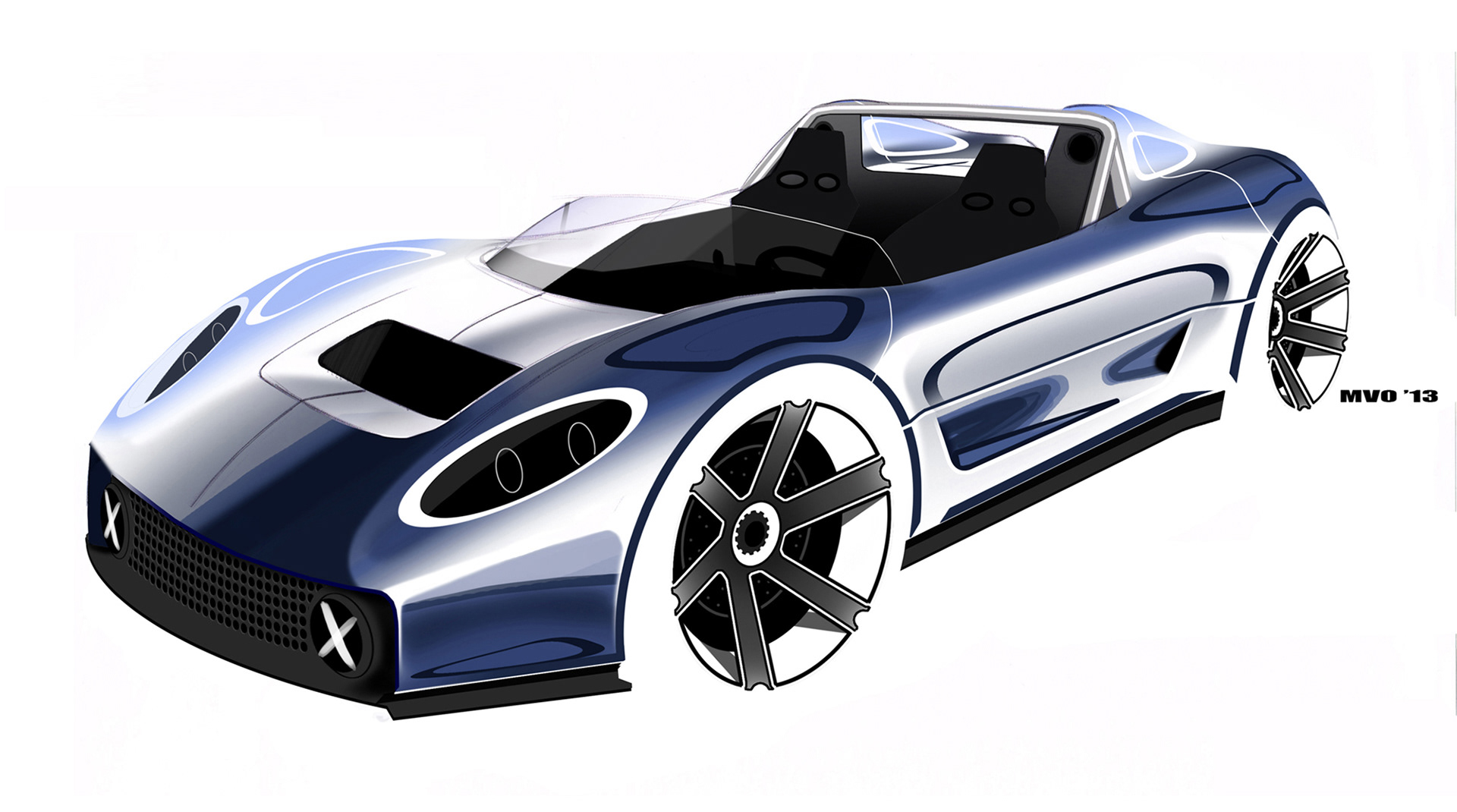

Me and my brother Andries van Overbeeke, artist and CAD-modeller, created the exterior design for the new Silvermine 11SR, a track day dedicated race car. We developed the design form the first sketch to the final CAD files.

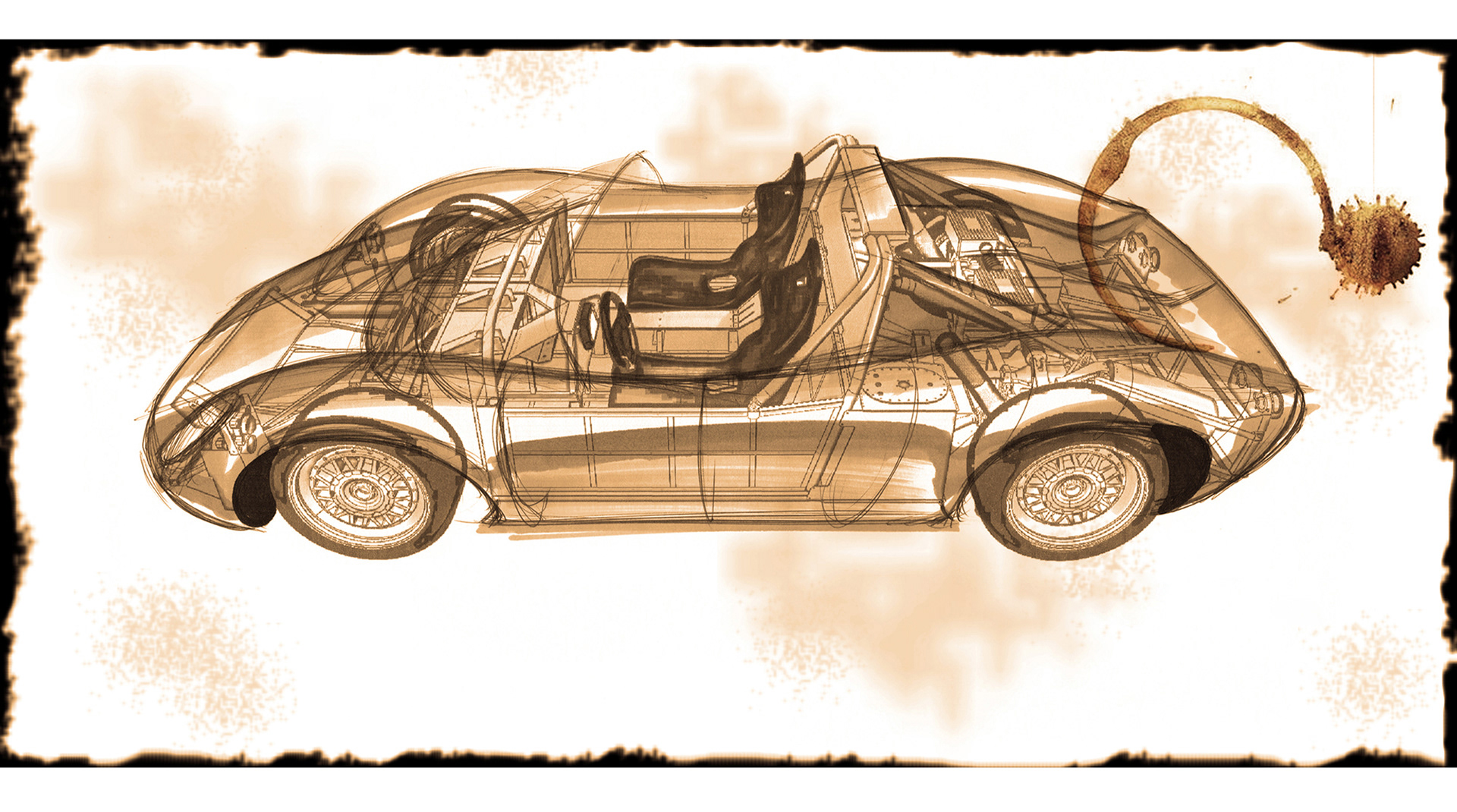

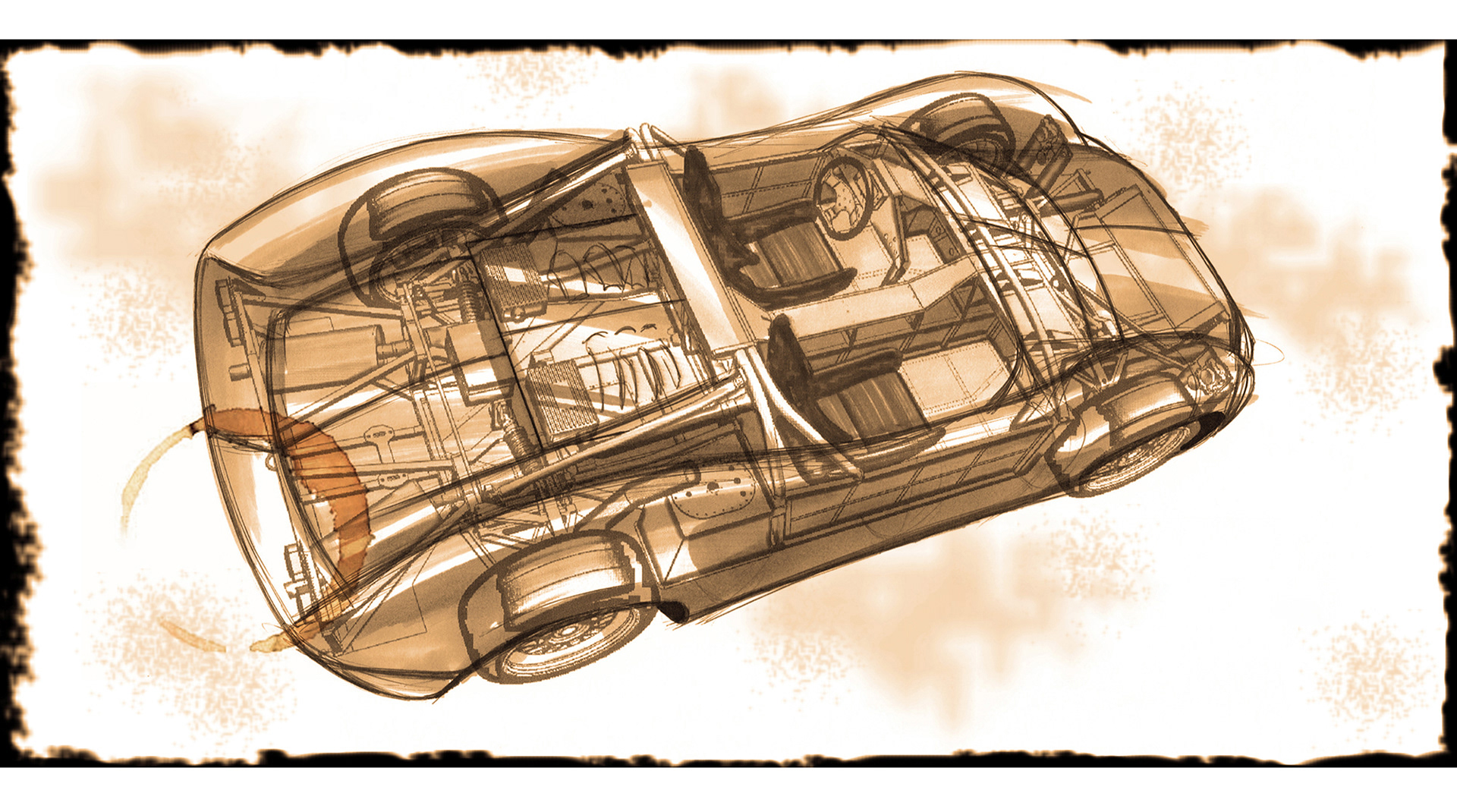

Usually, engineering and exterior/interior product design happen simultaneously within an integrated design process. However, in this case there was a unique situation because of the unusual sequence of events. First the chassis had been developed. Then a tailored exterior had to be designed, tailored to fit. The 11SR is the embodiment of Van Rouendal’s racing and engineering dreams. Quite uniquely, his straight forward approach to create this lightweight chassis eventually also inspired us very much during the exterior design process. This is the main reason a choice was made to not cover the raw chassis completely, but show the craftsmanship in certain places.

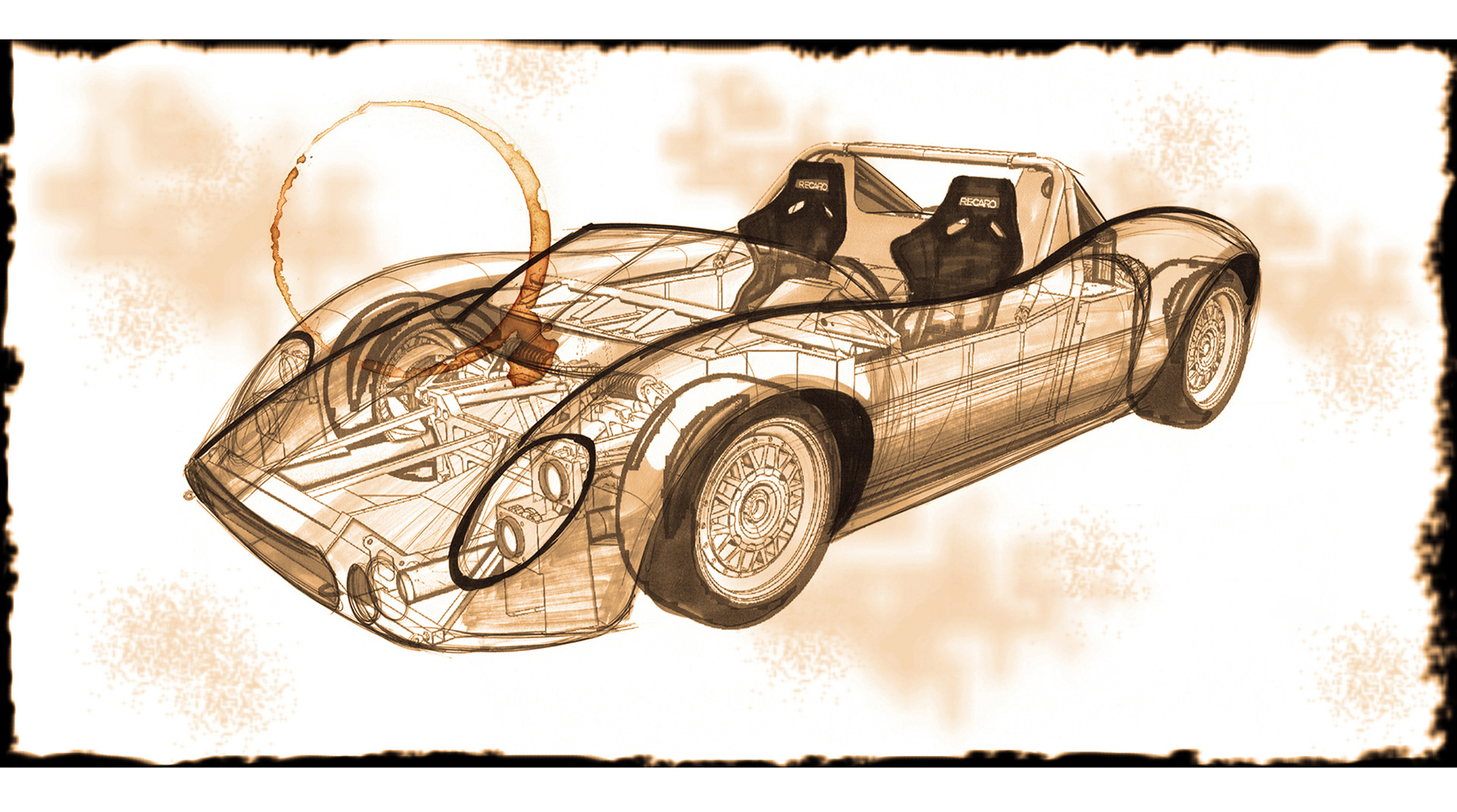

We tailored the new exterior around the hard points the chassis provided us with. The main challenge for us was to play with the high contrast between curved and sensual body work and the hard core rigid chassis, and especially where the both meet. Inspired by the great race car heritage of the 50’s-60’s-70’s, a design has come to life evoking echoes of a bygone era. As the new design evolved, these familiar lines were rediscovered and carefully penned down into a recognizable new blend. The result is a timeless design, a car that induces associations with highlights from the past. It is not intended as a retro design, but a deliberate search for where old meets new, where nostalgia meets contemporary engineering.

Classically sensual lines meet a very straight-forward and functional race chassis. The design is clean with very few lines and contains a classic curved beltline, voluptuous wheel arches and classic surface treatment. The air ducts are kept simple and purely functional, no excessive design is applied. The form language of some elements are inspired by elementary fabrication techniques, like the front nose grill (milling aluminium), side skirts and rear diffuser (pressing and bending sheet metal).

At the rear, the exposed chassis frame shows its raw engineering and functionality. Underneath the tailgate, the engine bay is visible as is the gear lever mechanism and the adjustable rear suspension. The complete exhaust system is not even styled at all. The front suspension is visible through the wind shield which on itself is also part of the nose air duct outlet. Opening the front and rear hood, exposes the carefully crafted chassis with bolt-on sub frames and adjustable suspension with the one-of-a-kind up-rights.

The off-the-shelf headlights and the brackets on which they are mounted, are maintained as Van Rouendal has originally fabricated them. They are fully visible through the front light panel, providing also a peak into the car’s front internals. The transparent engine cover exposes the longitudinally placed 325 hp Subaru 3.0 liter six-cylinder boxer engine. One of the most exquisite and remarkable pieces of engineering on the car is the exposed gearshift system.

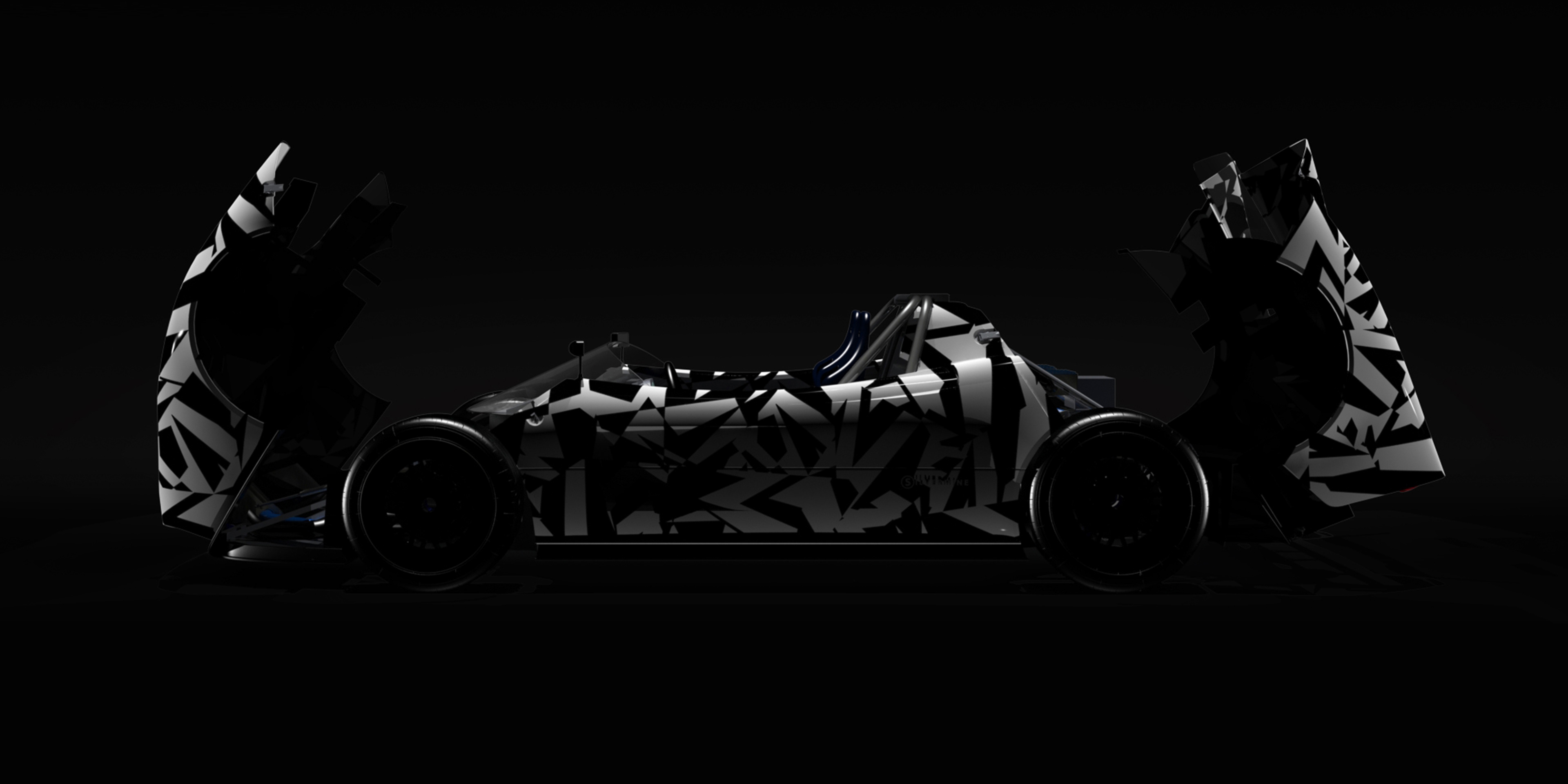

(below) Teaser renderings that were released in the press.

(below) Testing at race track Meppen (Germany). Photos by Marco van Overbeeke

(above) Blurred Silvermine at speed, photos by Marco van Overbeeke